Water jet cutting is one of the most advanced and adaptable fabrication techniques available, offering precision and efficiency in a wide range of applications. Whether used in manufacturing, automotive, aerospace, or even artistic projects, this process provides a level of accuracy that is hard to match with traditional cutting methods. Here, we get into the fascinating land of waterjet cutting and explore how this technology works and its many advantages.

What is water jet cutting?

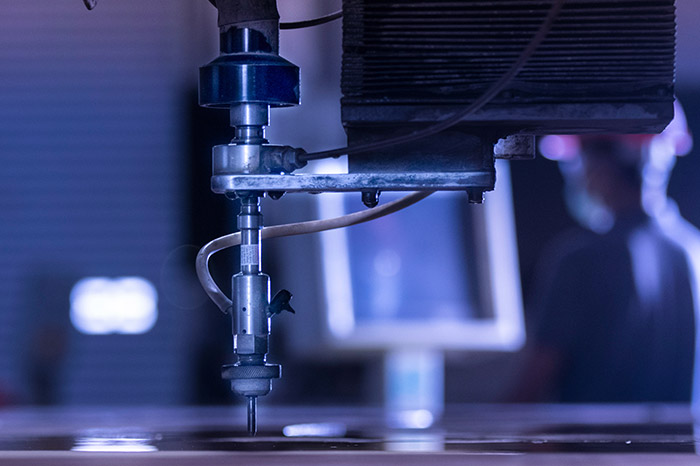

Water jet cutting is a process that uses a high-pressure stream of water, often mixed with an abrasive substance, to cut through materials. Unlike other cutting methods, which use heat, water jet cutting relies on the force of water, making it ideal for materials that are sensitive to heat. This technique is incredibly versatile and can be used to cut materials as soft as rubber or as hard as metal and stone.

Types of water jet cutting:

There are two main types of water jet cutting:

Pure water jet cutting: This method uses only high-pressure water to cut softer materials like foam, paper, or plastic. It is ideal for applications where precision and a clean finish are essential.

Abrasive water jet cutting: In this technique, a fine abrasive material, typically garnet is mixed with the water. This abrasive improves the cutting power, allowing for the cutting of harder materials such as steel, ceramics, and glass.

Advantages of water jet cutting:

Water jet cutting offers several key benefits that make it a preferred method in many industries:

No heat-affected zones: Since there is no heat involved, the material retains its structural integrity. This is particularly important for metals and composites that may warp or weaken under high temperatures.

Precise cuts: The technique offers high precision, with the ability to cut intricate shapes and details, making it perfect for custom designs and detailed fabrication work.

Eco-friendly process: Water jet cutting produces no harmful fumes or emissions, and the water used in the process can be recycled, making it an environmentally friendly option.

Applications of water jet cutting:

Water jet cutting is widely used in various industries due to its versatility. It’s used in the automotive industry for cutting components, in aerospace for precision machining, and even in the construction of stone and tile projects. Artists also take advantage of the technique for creating detailed sculptures and architectural elements.